Amplifier Corvette 068. Audio and video equipment repairman in Barnaul

<з>Amplifier Corvette 100U-068S. Fundamental electrical diagram amplifier and its blocks, photo and appearance of the device. To download the diagram or part of it, right-click on the picture and then select Save image.

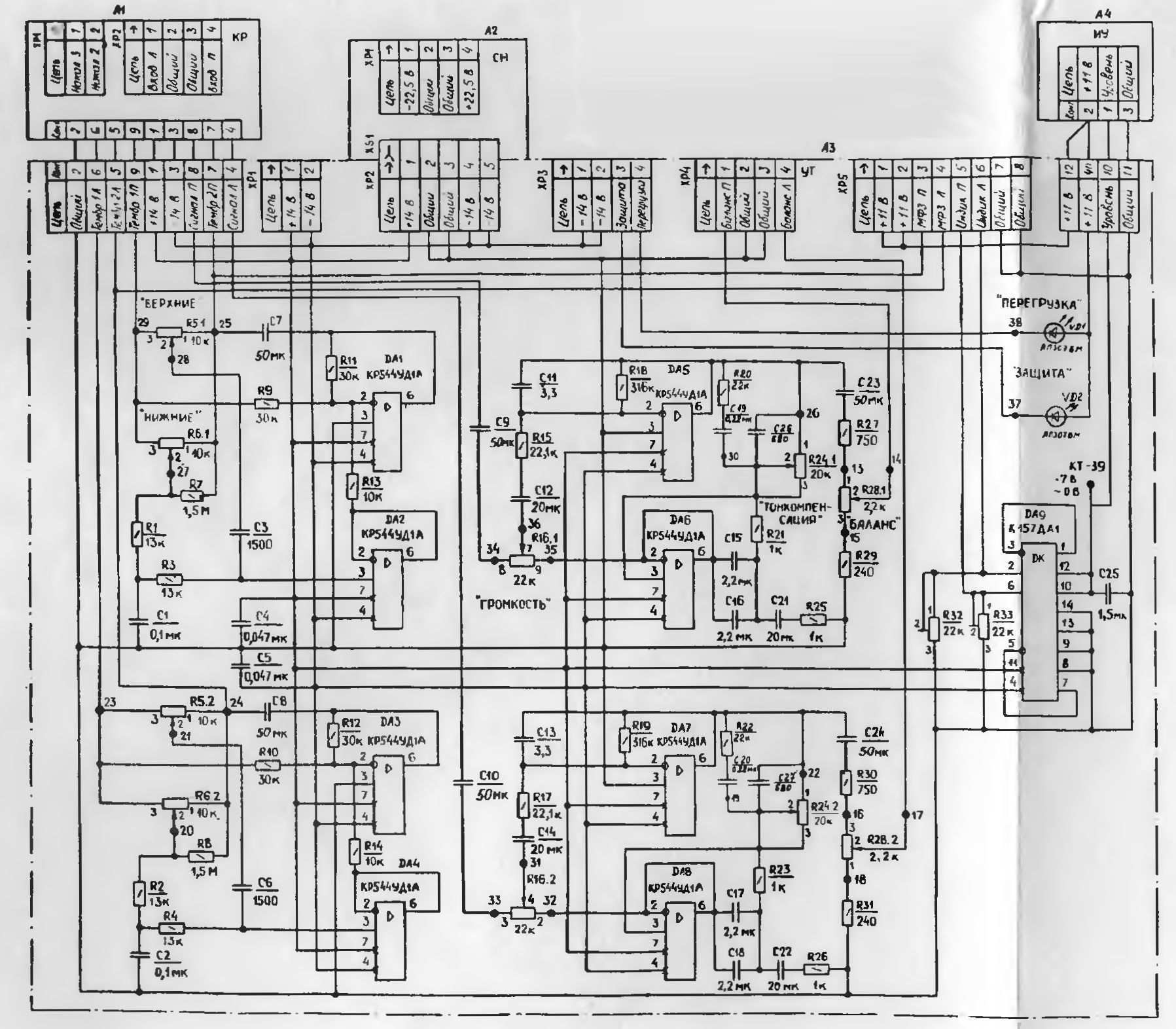

Wiring diagram for the Corvette 100U-068S amplifier blocks.

Layout of components for the Corvette 100U-068S amplifier.

DC voltages are measured without a signal. Signal frequency -1000 Hz. VOLUME and BALANCE controls are in position 0. The recommended type of device is Ts4341 or V7-22.

* Resistors R32 and R33 of the UT board regulate the ignition threshold of the output power indicator, R17 and R18 of the CA board regulate the stabilized supply voltage. The conclusions of KR544UD1, K561LA7, SN046, SKP40, PKN61, PKN41, sockets, PP3-44 are given conditionally.

Accepted abbreviations: PA - power amplifier; SG protection of the rectifier;

PZ - contactor board, UV - rectifier device, DT - telephone divider, OU - level limiter; KZ - comprehensive protection; UK - correction amplifier; UT - timbre amplifier; BUT - tone amplifier block, CH - voltage stabilizer, KS - signal switch, KR - mode switch, IU - level indicator; RG - volume control.

Corrective amplifier UK.

Scheme of the integrated protection unit (CP).

PZ contactor board.

Telephone divider DT.

Op amp level limiter.

ULF output power level indicator (IU).

RG volume control.

Rectifier protection circuit (RP).

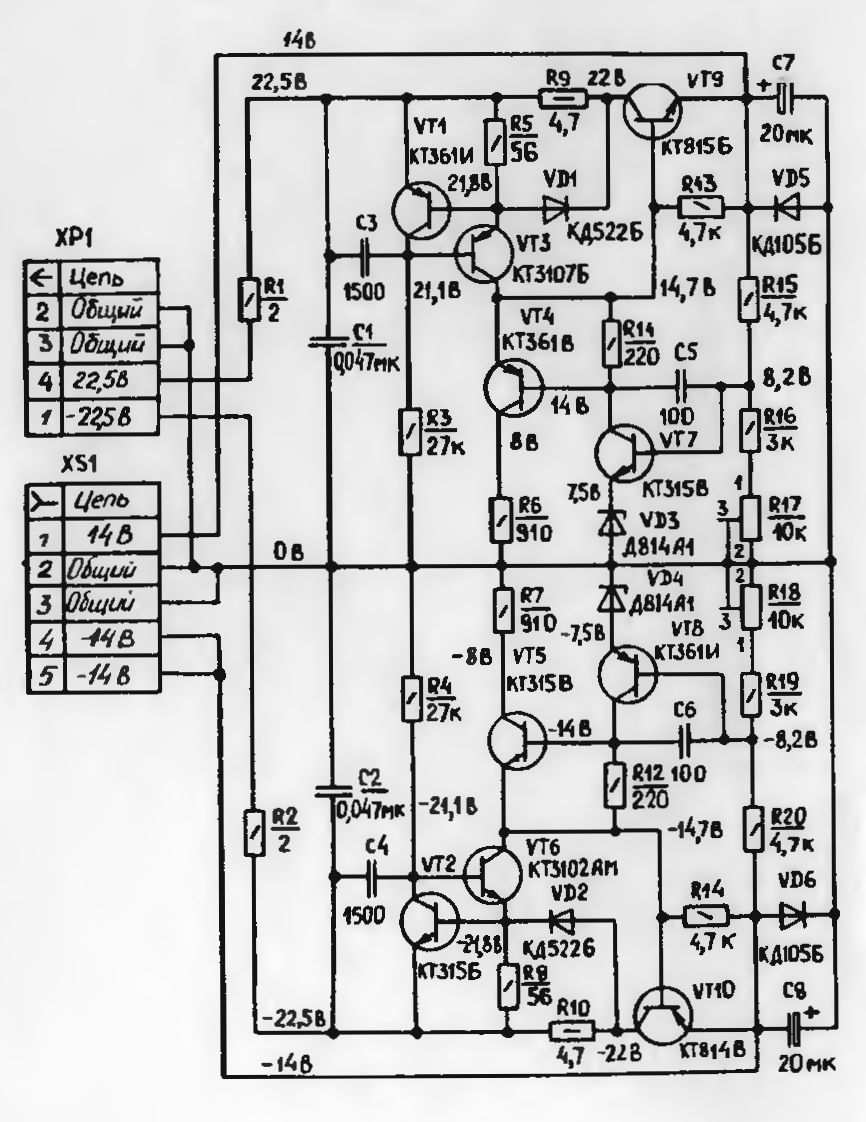

Voltage stabilizer (SV) circuit.

Schematic diagram of a power amplifier (PA).

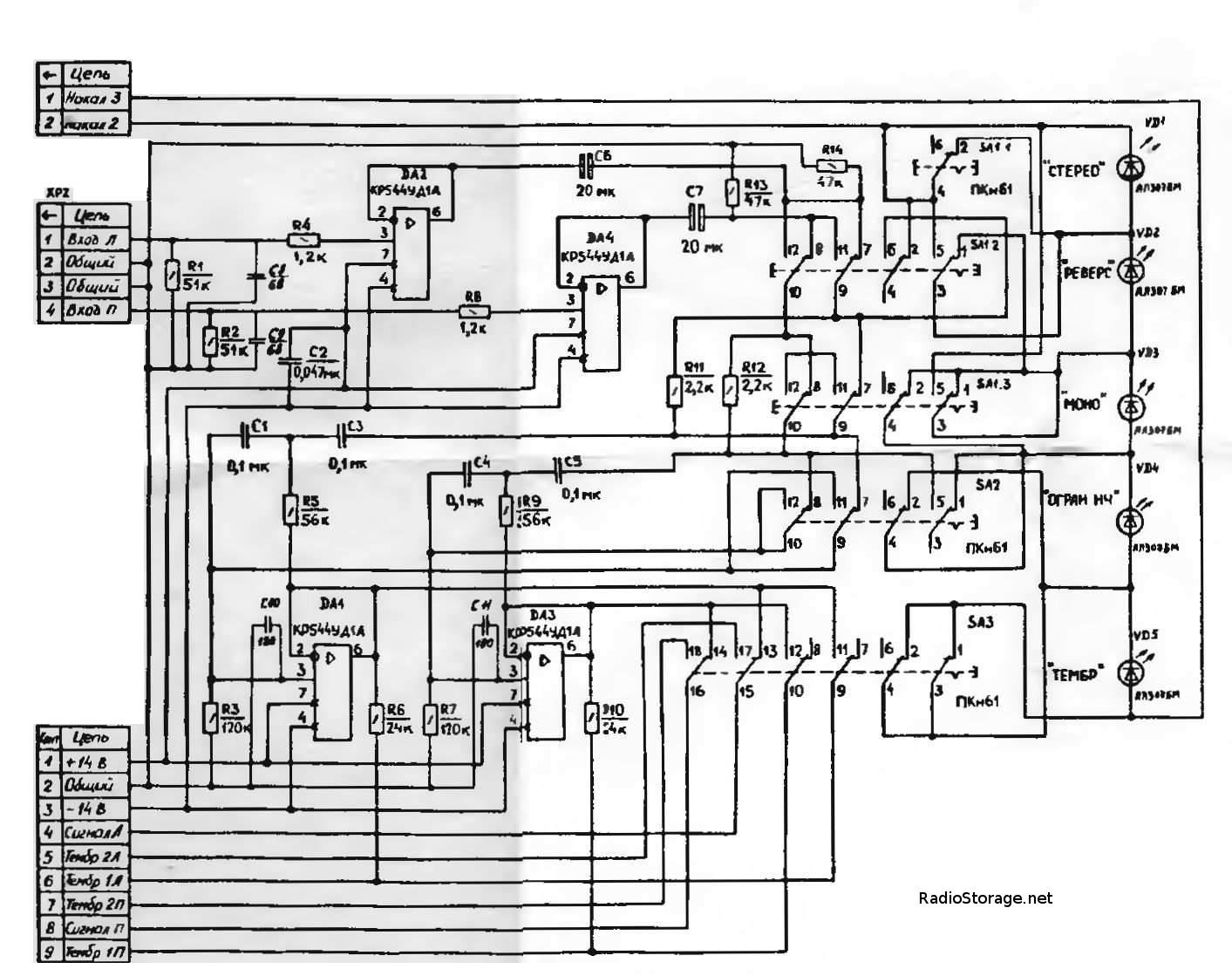

KR mode switch.

Diagram of a rectifier device (RD).

KS signal switch.

Pinout of parts and components used in the Corvette 100U-068 amplifier.

Amplifier Corvette 100U-068S 1993 release. The amplifier is complete, has a layout similar to an amplifier Brig 001. The power amplifier has two separate supply voltages. +-23V and +-42V.

Brief description of the amplifier. Amplifier weight 7 kg. The power transformer is covered with a metal shield, but not completely covered. It is small in power, about the same as in an amplifier Brig 001. The amplifier body is assembled on a metal chassis, which is a sheet of metal approximately 0.4 mm thick. with holes for ventilation. Power amplifier boards, a power supply capacitor block, a power transformer, a pre-amplifier and a tone control unit are secured to this sheet with screws. All modules are secured with screws - similar to self-tapping screws. The amplifier is closed on top with a lid that is aligned with the front front panel amplifier The front panel of the amplifier is plastic, black. The plastic is rather weak and prone to wear, so over time the volume, tone, and balance knobs may become “worn.” Also on the buttons. It is possible to cover the front panel with varnish or other composition to preserve appearance. KRYLON varnishes can be used to coat plastic.

The slider-type volume control is assembled from resistors, the same as on the Odyssey-010 amplifier. Only in the Odyssey, all controls are assembled from permanent resistors. In the Corvette, the remaining controls - balance, tone, loudness - are simple variable resistors SP3-33. Over time, they also become unusable, the track wears out or breaks off. Each button is illuminated with a separate light. Miniature CMN light bulbs are used as illumination, shining through a red filter built into the front panel. You get red glowing red dots opposite each button.

Appearance of the amplifier.

View of the amplifier with the cover removed.

Internal layout of the amplifier.

Separately, we should talk about the backlighting of the buttons, since everyone is faced with burnt out light bulbs. The buttons are illuminated by miniature SMN lamps of 10-12 Volts. The voltage on the lamps is approximately 9 Volts. The bulbs cost 5 pieces each in special plastic blocks, thin antenna leads are threaded into the holes and soldered to the output points. In this amplifier, some of the bulbs have already failed. You can replace them with the same ones, you can find them. If you replace light bulbs with LEDs, it will be more preferable and beautiful. In order to replace light bulbs with LEDs, you need to do the following: LEDs need to be taken white. You can also take red LEDs, but since there are already red filters in the front panel, I don’t see the point in installing them. The light filters in the front panel are convex on the inside and convex on the outside. those. on the front they look like red dots. Therefore, if you install 3mm LEDs, they will not fit. Their leads can be inserted into the holes in the plastic block, but from the outside they will stand out for their entire length. Therefore, when we close the lid with the front panel, it will not close, the 3mm LEDs will interfere due to the convex filters, and the 3mm LEDs themselves are large.

It is necessary that the LEDs are completely inserted, just like the paws, into the round cells, seats and did not protrude even a millimeter. Otherwise, the cover with the front panel will not close. I picked up these 1.8mm LEDs, with a flat top part. They fit perfectly in size and do not protrude beyond the cell. At the same time they shine brightly in white. The second question is how to match them in terms of supply voltage. The light bulbs receive a voltage of about 9 volts. To power the LEDs you need 3 Volts. It is necessary to take 300 Ohm resistors with a power of 0.25 W and connect them in series to each LED. You can calculate the resistor resistance using the formula that is available on the Internet. At the same time, the voltage on the LED is limited to 3 Volts, which is what we need. It all looks like this:

Replacing backlight bulbs with LEDs.

300 Ohm resistors need to be installed on the LEDs in two blocks, which each held 5 pieces. light bulbs The 6-light block, which is located next to the recording input switches, will be connected differently. There is no need to install resistors on these LEDs. They already have 3 Volts. If you put resistors on them, the LEDs will not light up at all, because there will be a voltage drop across them. We have made changes to the amplifier circuit and therefore need to take this into account. It looks like this:

LEDs without limiting resistors on the right side of the recording input switches.

Another nuance - when connecting LEDs, you should take into account the polarity, because the voltage is constant.

Illuminated buttons with new LEDs.

P.S. In amplifiers SANSUI Miniature light bulbs are also used for illumination. They can also be replaced with LEDs, but you just need to take into account that the voltage on them is variable and you will also need a diode to rectify the alternating voltage.

The Corvette 100U-68S amplifier has differences in electronic components depending on the year of manufacture. Early versions of the amplifier were equipped with 2 pcs power supply filter capacitors of 15000 µF x 63V. The capacitors were the same as in the Odyssey 010 - K50-37 amplifier. Later releases of the amplifier already had other capacitors - 2200 µF x 63V, which were made up of several capacitors, giving a total of 15,000 µF for each arm.

By the way, in the Odyssey - 010 amplifier, later releases also used 2200 μF x 63V capacitors made up of several pieces. And the metal volume and tone control knobs on the early versions of Odyssey - 010 had “notches” for ease of adjustment; on later versions they were no longer “notched”, but simply round.

Later Corvettes went even further and replaced the output transistors in metal cases KT865 for transistors in plastic cases like KT8101. The version I got is from 1993. And the capacitors and transistors in it have already been replaced in the direction of cheaper ones, or in the 90s the collapse of the Union was already underway.

I decided to replace the 2200 μF x 63V capacitors with new ones, since there was no trust in them. The replacement was made with Jamicon capacitors.

We will install such capacitors in each arm with a voltage of +-42V. You get 16,000 microfarads for each arm.

We are replacing electrolytic capacitors in the power filter.

It is also necessary to carry out maintenance on the volume control resistor. To do this, it must be removed and disassembled. Wipe the contact fields from dirt with alcohol, lubricate all rotating parts with new CIATIM-201 lubricant.

There was another problem with this example of the amplifier. One channel disappeared periodically. The reason turned out to be simple, but finding it was not so easy. The contact on the power amplifier board connector was not soldered. After soldering all the contacts of the power amplifier board connector, the sound became normal and did not interrupt.

Also, another feature of the Corvette amplifier that many encounter is clicking after turning off the amplifier. This amplifier had them too. The first thing you need to do is replace the 22 µF capacitor C2 in the protection unit with a new one and solder separate wires to its terminals, which need to be connected to the free contact group of the PKN network switch. Thus, by turning off the amplifier, we discharge capacitor C2, which does not have enough time to discharge. Perhaps this is due to a change in the circuit to replace light bulbs with LEDs.

The sound of the amplifier is decent. Excellent sound, there is dynamics, it does not color the sound like some amplifiers. There is enough power to spare. The built-in LED power indicator allows you to focus on the power, although it is limited to one channel. Therefore, in order to maintain decent sounding of the amplifier, you need to replace the power filter capacitors. The remaining capacitors can be changed as needed. Some of them are non-polar, some are electrolytic.

The disadvantage of the amplifier is its heating. It is already starting to heat up when working on the headphones. This is the mode of the output transistors, which have a separate power supply of +-42 Volts. When operating for a long time at high volume, it will get very hot, so you can install a fan to blow the heatsinks of the output transistors; by the way, the heatsinks in it are small.

When developing the Corvette amplifier, the experience of creating the Brig-001 amplifier was taken into account. It will be of interest to fans of Brig.

Speaker system Corvette 150AC-001.

Acoustics Corvette 150AC-001- I will describe the features of this acoustics. I'll compare it with 35AC-018 Amphiton.

The acoustics are made of chipboard panels and are made quite neatly. All chipboard panels fit perfectly evenly. The acoustics are painted black, most likely my copies have original black paint. I’ll immediately note the thickness of the walls of the Corvette acoustics. The front wall is made of plywood 25mm thick. In Amfiton 35AS-018, the thickness of the front wall made of chipboard is 38mm, but this is understandable, Amphiton 018th is the leader in front wall thickness among Soviet acoustics of the 35AC series. The woofer in this acoustic system is quite large in size - 300mm. This is 100GDN-3. There are two spacers inside the case - one between the tweeter, the other located vertically along back wall acoustic housings. Spacers compensate for the rigidity of the body and the lack of thickness of the front wall.

Everything inside also fits well, there are not the slightest gaps. The rather large 100GDN-3 woofer takes up almost half the volume of the cabinet. Here, of course, a more voluminous case would be needed. The 30GDS midrange speaker is installed on top of the 10GDV-4 tweeter, which is also unusual. The midrange speaker is insulated inside with a cardboard cylinder, which rests against the rear wall of the housing, while creating additional rigidity of the housing.

Wiring in acoustics. What can be noted about it? Made with dignity, the wiring is woven with black thread and neatly laid out. What can you say about acoustic wiring? Amphiton 35AS-018. It uses single-core wire, which is of poor quality and thin. Which definitely needs to be changed. There is no need to change the wiring in Corvettes. It is stranded and thick.

At the bottom inside the case there is a filter on a separate board and a protection board. Protection is connected via a separate connector on the rear wall speaker system. The screw clamps are good, but they loosen over time. You need to glue a textolite strip inside the case epoxy resin, tighten the screws and then the screw clamps will work normally.

In my copy, the 100GDN-3 woofer turned out to have a homemade suspension. The pendant was made from rubber seal for windows. Of course, such a suspension will not work normally and it must be replaced with a factory one.

Also, the 10GDV-4 tweeter did not work. There was a break inside the coil.

The sound-absorbing material inside the case is a wad of cotton wool glued in the middle to the rear wall of the case. It is unknown whether the developers proceeded from the volume of sound-absorbing material, but the volume of wool in the two buildings is different. The cotton wool, located in a single lump in the middle of the body, touches the wiring, part of it blocks the hole in the bass reflex pipe, and cotton wool remains are scattered everywhere inside the body. To carefully lay the cotton wool, you can secure it with a piece of gauze. Attach the gauze with a stapler.

Manufacturer: Kirov plant "Ladoga", 1990.

Purpose: amplifier "Corvette 100U-068s" of the highest complexity group is designed for two-channel amplification and switching of low frequency signals from various sources sound programs.

Diagram and instruction manual in archive on Yandex.Disk of our website.

Main technical characteristics:

Frequency range: 10 – 70000 Hz

Frequency response unevenness, relative to 1000 Hz in the range:

10-70000 Hz: ±1.5 dB

20-20000 Hz: ±0.3 dB

Output power limited to 1% distortion: 95 W/4 ohms

(same with limiter: 60 W/4 Ohm)

Continuous power: 125W/4ohm

Short-term power: 150W/4ohm

Deviations of the frequency response of the correcting amplifier from the specified one in the range:

10-40000 Hz: 2 dB

20-20000 Hz: 0.5 dB

Harmonic distortion under normal operating condition: 0.007%

2nd and 3rd order intermodulation distortion: 0.05%

Crosstalk attenuation between channels at 1000 Hz: 60 dB

Connected speaker impedance: 4 Ohm

Signal to noise ratio: 66 dB

Power consumption from the network:

no load: 30 W

nominal 200 W (at 8 ohm load)

nominal 275 W (with 4 ohm output load)

Amplifier size (WxHxD): 430x120x385 mm

Amplifier weight: 9.7 kg

Description:

This amplifier is a representative of the new generation of complete AF amplifiers. In its creation, technical solutions of a high-quality amplifier "" were used. For the first time, a power amplifier of the LAN class with two-level power supply was used. This mode made it possible to improve the thermal conditions of the amplifier.

The amplifier has protection against short circuit in the load or overload of the outputs. The model has a pickup switch, with which, in addition to the electromagnetic one, you can also connect an electrodynamic one with moving coils. The amplifier allows simultaneous and independent recording of programs from different sources onto 3 tape recorders. The instantaneous maximum power value is indicated by a 12-segment LED indicator. The maximum level limiter allows you to reduce the output signal when using speakers with a power lower than the recommended one. A volume control with a smoothly variable loudness level allows you to reduce noise when lowering the volume, and by selecting the desired increase in the frequency response in the low-frequency region, it is better to coordinate individual characteristics auditory perception with acoustic properties in the listening room.

For additional adjustment There is a button for changing the volume in steps. Interference at infra-low frequencies from electronic control units and body vibrations is limited by a high-pass filter, and high-frequency interference from gramophone records is limited by a low-pass filter. Switching programs, speakers, headphones, etc. made by push-button switches, with light indication of the mode. Switchable output electrical network allows you to power other devices working in conjunction with the AF amplifier.